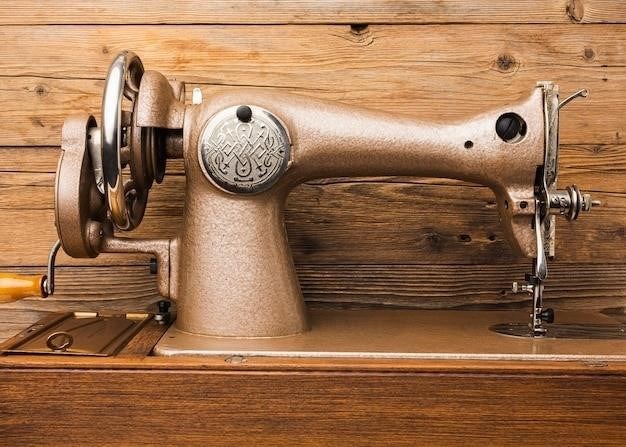

Manual Old Singer Sewing Machine⁚ A Guide

This comprehensive guide delves into the world of manual old Singer sewing machines, offering insights into their history, identification, types, mechanics, maintenance, troubleshooting, and resources. Discover the fascinating history of Singer sewing machines, learn how to identify your model, understand the different types of manual machines, and gain valuable knowledge about their mechanics. This guide also provides essential tips on maintenance and care, troubleshooting common problems, and accessing helpful resources and support. Join us as we explore the timeless appeal and enduring value of these iconic machines.

Introduction

In a world dominated by advanced technology, the allure of vintage sewing machines, especially those crafted by Singer, continues to captivate enthusiasts. These robust, time-tested machines represent a bygone era of craftsmanship and ingenuity, offering a unique blend of functionality and nostalgia. While modern sewing machines boast a plethora of automated features, manual Singer machines possess a charm and simplicity that appeals to both seasoned sewists and those seeking a hands-on approach to the craft.

Manual Singer sewing machines are not merely relics of the past; they are valuable tools that can be revitalized and enjoyed for generations to come. Whether you’re a seasoned seamstress or a curious beginner, the world of manual Singer machines offers an engaging and rewarding experience. This guide aims to provide you with the knowledge and resources needed to appreciate, maintain, and utilize these iconic machines, ensuring their continued relevance in the tapestry of modern sewing.

Beyond their practical use, manual Singer machines hold a special place in the hearts of many. They are often passed down through families, carrying with them stories of creativity, resilience, and the enduring spirit of DIY. As you delve into the world of manual Singer machines, you’ll discover the fascinating history behind their design, the unique characteristics of different models, and the timeless techniques that make them so cherished.

History of Singer Sewing Machines

The story of Singer sewing machines is intricately woven with the fabric of American innovation and industrialization. The company’s roots trace back to 1851, when Isaac Merritt Singer, a visionary inventor, developed a revolutionary sewing machine that revolutionized the garment industry. Singer’s invention, a treadle-powered machine with a patented “lock stitch” mechanism, marked a significant departure from the cumbersome and unreliable sewing devices of the time.

Singer’s ingenuity was not limited to the machine itself. He understood the importance of marketing and accessibility. He established a network of retail stores, making sewing machines readily available to the public. He also pioneered the concept of installment plans, allowing individuals to purchase these revolutionary tools without a significant upfront investment. This innovative approach democratized sewing, making it accessible to a wider range of people, from homemakers to professional tailors.

Throughout the late 19th and early 20th centuries, Singer sewing machines became ubiquitous, transforming the way clothes were made and consumed. From the bustling factories of the Industrial Revolution to the cozy homes of rural communities, these machines became essential tools for creating garments, household items, and even artistic creations. The legacy of Singer sewing machines is one of ingenuity, accessibility, and the enduring power of human creativity.

Identifying Your Model

Identifying the specific model of your manual old Singer sewing machine is crucial for finding the right parts, manuals, and even appreciating its historical significance. Several key features can help you decipher its identity. First, look for the model number, often found on a metal plate or decal on the machine’s body or base. This number, typically a combination of letters and numbers, provides a direct identifier for your machine’s specific design and features.

Next, examine the machine’s design and construction. The shape of the base, the location and style of the hand crank, the design of the needle plate and feed dog, and the presence or absence of specific accessories like a bobbin winder or a needle threader can all provide clues about the model. Vintage sewing machine manuals and online resources like websites dedicated to Singer sewing machines can offer valuable information about identifying specific models based on their unique characteristics.

Finally, consider the machine’s age. If you have a vintage Singer, its age can be a good indicator of its model. For instance, hand-crank machines are typically older than electric models, and the presence of specific features like a cast iron base or a specific style of needle plate might be indicative of a particular era. By carefully examining these details, you can unlock the identity of your manual old Singer sewing machine and embark on a journey of discovery.

Types of Manual Singer Machines

Manual Singer sewing machines come in a fascinating array of types, each with its own unique features and capabilities. One of the most common types is the hand-crank machine, often found in vintage sewing collections. These machines rely on a hand crank to power the needle’s up-and-down motion, offering a simple yet effective sewing experience. Hand-crank machines are known for their durability and ability to handle various fabrics, making them ideal for both basic sewing tasks and more intricate projects.

Another popular type is the treadle machine, which uses a foot pedal to power the needle. These machines offer a smoother sewing experience compared to hand-crank models and are often favored for their ease of use and ability to handle larger projects. Treadle machines typically feature a larger work surface and a stronger frame, making them suitable for quilting, upholstery, and other tasks that require a larger sewing area.

Beyond these classic types, there are also specialized manual Singer machines designed for specific purposes. For instance, some models were specifically designed for tailoring or dressmaking, featuring features like adjustable stitch lengths and tension settings to accommodate different fabric types and sewing techniques. Others were geared towards industrial applications, boasting powerful motors and robust construction to handle heavy-duty tasks.

Understanding the Mechanics

Unraveling the inner workings of a manual old Singer sewing machine reveals a fascinating blend of ingenuity and simplicity. At the heart of these machines is a system of gears, levers, and a bobbin case, all working in harmony to create stitches. The hand crank or treadle, depending on the model, sets the entire mechanism in motion. When you turn the crank or press the treadle, a series of gears transmit power to the needle bar, causing it to move up and down. Meanwhile, the bobbin case, located beneath the needle plate, holds a spool of thread, which is fed through a tiny hook that catches the needle thread to form a stitch. The bobbin case is responsible for creating the underside of the stitch, while the needle thread creates the topside.

The tension of the threads, both the upper and lower threads, plays a crucial role in the quality of the stitch. Proper tension ensures that the threads interlock evenly, resulting in a smooth and secure stitch. The tension can be adjusted using a knob or lever on the machine, allowing you to fine-tune the stitch depending on the fabric and sewing technique. The feed dog, located beneath the needle plate, moves the fabric forward with each stitch, ensuring that the fabric is fed consistently and smoothly through the machine.

Understanding the mechanics of a manual Singer sewing machine is not only crucial for using the machine effectively but also for maintaining it properly. By grasping the interplay of the different parts, you can better identify potential problems and address them efficiently, keeping your machine running smoothly for years to come.

Maintenance and Care

Preserving the longevity and functionality of your manual old Singer sewing machine requires consistent maintenance and care. Regular cleaning and lubrication are essential to keep the machine running smoothly and prevent wear and tear. Begin by gently brushing away dust and lint from the machine’s exterior, paying attention to the needle plate, feed dog, and bobbin case area. Use a small brush or a vacuum cleaner with a brush attachment for this purpose. Next, carefully remove the needle and needle plate, and clean them thoroughly using a cloth dampened with rubbing alcohol. Be sure to dry them completely before reassembling.

Lubricate the moving parts of the machine, such as the needle bar, bobbin winder, and hand crank, with a light sewing machine oil. Apply a small drop of oil to each moving part and then gently move the parts to distribute the oil evenly. Avoid over-lubricating, as this can attract dirt and lint. After lubricating, wipe away any excess oil with a clean cloth. It’s also essential to check the tension of the upper and lower threads regularly, adjusting them as needed for optimal stitch quality.

Storing your machine properly is crucial for protecting it from dust and damage. Cover the machine with a dust cover or a soft cloth when not in use. Store it in a dry and cool place, away from direct sunlight and moisture. Following these simple maintenance and care practices will ensure that your manual old Singer sewing machine continues to sew beautifully for many years to come.

Troubleshooting Common Problems

While manual old Singer sewing machines are known for their durability, they can occasionally encounter issues. Understanding common problems and their solutions can save you time and frustration. One common problem is skipped stitches, which can be caused by improper threading, a bent needle, or a worn-out needle. Check your threading carefully, ensuring the thread is properly routed through all the guides and the bobbin is wound correctly. Replace a bent or worn-out needle with a new one of the appropriate size for your fabric. If the issue persists, inspect the needle plate for any burrs or damage that might be interfering with the needle’s movement.

Another common problem is uneven stitch length, which could be caused by incorrect tension settings, a loose bobbin case, or a worn-out bobbin winder. Adjust the upper and lower thread tensions until you achieve a balanced stitch. Ensure the bobbin case is properly secured and not loose. If the bobbin winder is worn out, replace it with a new one. If you experience difficulty threading the machine, check the threading diagram in your manual and make sure the thread is correctly routed through all the guides. If the machine is making unusual noises, such as grinding or clicking, investigate the cause, and address it promptly.

Remember to consult your machine’s manual for specific troubleshooting tips and guidance. With a little patience and understanding, you can resolve most common issues and keep your manual old Singer sewing machine operating smoothly.

Resources and Support

Navigating the world of manual old Singer sewing machines is made easier with a wealth of resources and support readily available. Online communities dedicated to vintage sewing machines provide a platform for enthusiasts to share their knowledge, experiences, and troubleshooting tips. Forums like the “Singer Sewing Machine” forum on SewingMachinesales.co.uk allow users to ask questions, seek advice, and connect with fellow owners. These online spaces offer a valuable hub for finding solutions to specific problems, obtaining guidance on restoration projects, and exchanging insights on machine models and accessories.

Numerous websites specialize in providing manuals and parts for vintage Singer sewing machines. Sites like SewingMachinesales.co.uk offer a comprehensive online parts database and a collection of downloadable manuals, including those for older models. These resources are invaluable for finding replacement parts, understanding machine features, and resolving operational issues. Additionally, antique sewing machine dealers and collectors often possess extensive knowledge and can be a source of information and support. By leveraging these resources, you can access a vast network of expertise and enhance your experience with your manual old Singer sewing machine.

Remember that seeking out a local repair shop specializing in vintage sewing machines can be beneficial, especially for more complex repairs or restoration projects. Their expertise and experience can provide valuable assistance in restoring your machine to its former glory.